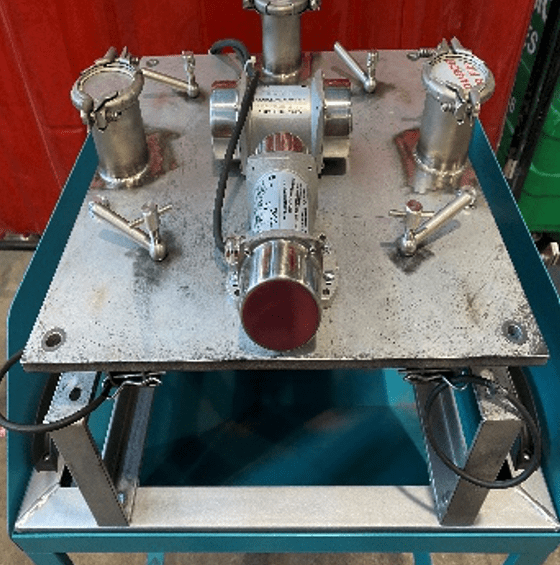

De-duster and dust extraction system

We were approached by one of our existing clients who was looking for help to solve an ongoing dust problem associated with the 3d printed components.

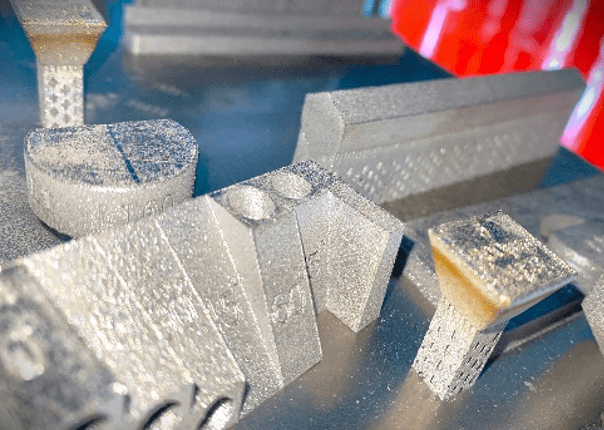

This customer was the leading manufacturer of titanium products. The process involved laying down a continuous layer of titanium in a honeycomb lattice to create the final product.

The microscopic honeycomb lattice however held very fine dust particles, as a by-product, which could not be removed by traditional methods alone.

RPL engineers looked at the process and suggested a different type of concept altogether as the dust was trapped within the component.

RPL carried out trials within our own manufacturing facility and concluded that to solve this issue we needed to design a bespoke machine to mount the components and to shake/vibrate them, the dislodged dust falls into a receiving hopper before being extracted into a wet collector dust extraction system.